- Waste management in Japan

- Circular economy in Japan

- Waste management in Asia

- Disaster waste management

Investigation of Short-Chain Chlorinated Paraffins in Automobile Shredder Residues

English translation: November 2022

Introduction

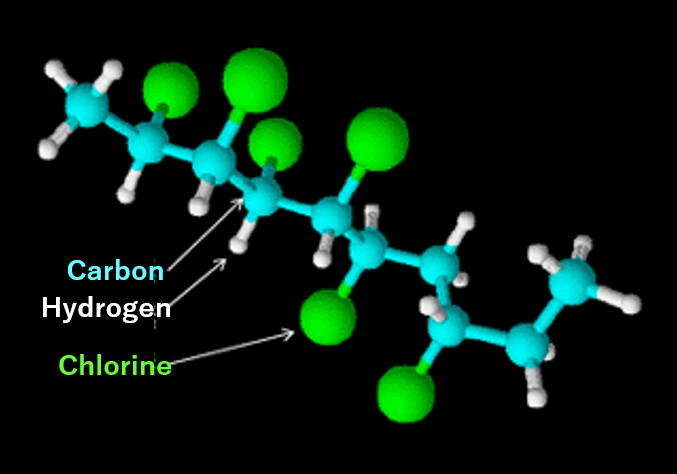

Chlorinated paraffins (CPs) are polychlorinated n-alkanes that have been widely used since the 1930s to the present. Their usages include the following: metal-working fluids and lubricants; plasticizers and additives in polyvinyl chloride (PVC) resins and flame-retarded rubber products (see our February 2014 article [in Japanese]); and tanning agents for leather products. With a molecular structure of hydrogen and chlorine atoms being bound to chain-like carbon atoms (Fig. 1), CPs are complex mixtures of a vast variety of molecules with different hydrogen and chlorine atom binding sites and numbers. The CPs having 10 to 13 carbon atoms are called “short-chain CPs (SCCPs)” and those with 14 to 17 carbon atoms are called “medium-chain CPs (MCCPs).” Those with 18 to 30 carbon atoms are called “long-chain CPs (LCCPs).”

Among these CP types, SCCPs have been studied by researchers around the world since the 1980s. They have reported various findings: SCCPs persist in the environment; SCCPs travel long distances with air and water if they evaporate or are discharged into rivers and oceans; SCCPs can accumulate in the bodies of living organisms; and SCCPs can be hazardous to organisms and the environment. Consequently, in May 2017, SCCPs were listed as a persistent organic pollutant (POP) in Annex A of the Stockholm Convention on Persistent Organic Pollutants (POPs), like polychlorinated biphenyls (PCBs) and dichlorodiphenyltrichloroethanes (DDTs) (chlorinated organic pesticides), to strengthen environmental regulations such as a global ban on their production and use.1)

Under these circumstances, our research team has been engaged in a series of studies to ensure proper storage and treatment processes for the wastes containing SCCPs. More concretely, we have been investigating the amount of SCCPs in various types of wastes, and to what extent waste storage or treatment processes release them into the environment. Among these wastes, we have focused on materials called “automobile shredder residues (ASRs)” that are left after machine crushing and shredding end-of-life vehicles (ELVs) and recycling metals such as iron, aluminum, and copper. Because ASRs normally contain many PVC resin parts that are used for electric wire insulation as well as flame-retarded rubber parts, we assumed that SCCPs would be found in them as well. This article will introduce our findings on the amount of SCCPs in ASRs.

How can we measure SCCPs in ASRs?

We conducted a survey at an ASR recycling facility in Japan that had been recovering metals (e.g., iron, aluminum and copper) and plastics from ASRs by various means: air classification which separates items by blowing air; magnetic separation which uses magnet to separate certain items; and float/sink separation which sorts items floating in liquids from the ones that sink.

At the facility, we collected the following six ASR fractions as samples (Fig. 2):

- Lightweight materials such as polyurethane foams sorted from ASR by blowing air

- Lightweight materials such as plastics sorted by stronger blowing air from the materials that remained after the separation process (i)

- Mixed materials sorted by magnetic power (e.g., metals such as iron, aluminum and copper, and plastics)

- Materials such as heavy plastics that were not attracted by magnet in the sorting process (iii) and floated in water whose density was 1.0.

- Materials such as PVC resins and rubber products that sank in water in the process of (iv) but floated in a special liquid whose density was 1.6.

- Refuse paper and plastic fuel (RPF) made from solidified waste plastics by mixing (i), (ii), (iv) and (v).

They were taken to our laboratory for detailed SCCP measurements. We crushed the samples and extracted organic compounds by adding acetone and toluene solvents. Then, we precisely measured SCCP concentrations in the extracts.

Our findings on SCCPs in ASRs

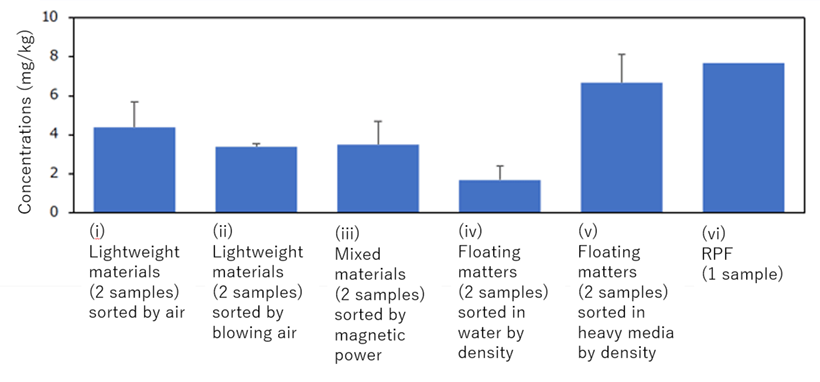

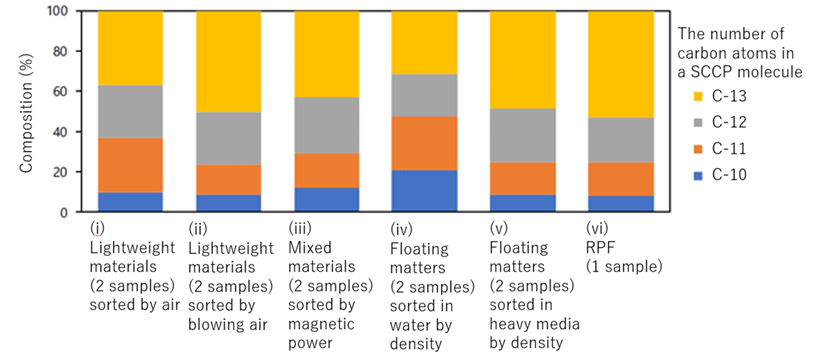

The SCCP concentrations in the ASR samples (i) through (vi) were in the range of 1.7 to 7.7 mg/kg (Fig. 3). These values were at least one order of magnitude smaller than the provisional low POP content values2)(100 or 10,000 mg/kg)set by the Basel Convention to decide whether decomposition treatment is required. As for the composition (percentage of each component), SCCP molecules with 13 carbon atoms (C-13) made up the largest percentage of the SCCPs contained in the samples (Fig. 4).

These results showed a tendency that the SCCP concentrations suddenly increased in the ASR samples as the percentage of the larger number of carbon atoms increased. Therefore, it was likely that high concentrations of MCCPs were included in these samples in addition to SCCPs. Like SCCPs, certain MCCP components have been reported to persist in the environment, travel long distances across national borders, and can bioaccumulate3)4). We thus realized that MCCPs also need to be investigated. Out of the ASR samples (i) through (vi), high-density materials such as PVC insulation materials and flame-retarded rubber parts that floated in a liquid and sorted out showed high concentrations of SCCPs. As we had assumed, these results implied that the wastes containing many PVC insulation materials and flame-retarded rubber parts may potentially contain relatively high concentrations of SCCPs.

Future research directions

The ultimate goal of our research is to propose proper storage and treatment methods for the wastes containing SCCPs. This article introduced our investigation of SCCPs in ASRs. In future, at other ASR treatment facilities, we will investigate the amount of both SCCPs and MCCPs emitted into the environment. Specifically, we will focus on the wastes containing high concentrations of SCCPs and MCCPs such as PVC resins covering electric wires and flame-retarded rubber parts to examine how much these pollutants are discharged during ASR storage and treatment processes. We will continue grasping the actual conditions of the POPs, including SCCPs that were newly listed by the Stockholm Convention, and will compile information that is necessary for proper treatment and recycling of relevant wastes.

References

- United Nations Environment Programme (2016) Report of the Persistent Organic Pollutants Review Committee on the work of its twelfth meeting. UNEP/POPS/POPRC.12/11/Add.3.

- United Nations Environment Programme (2018) Draft technical guidelines on the environmentally sound management of wastes consisting of, containing or contaminated with short-chain chlorinated paraffins.

- Gawor A., Wania F. (2013) Using quantitative structural property relationships, chemical fate models, and the chemical partitioning space to investigate the potential for long range transport and bioaccumulation of complex halogenated chemical mixtures. Environ. Sci. Process Impacts 15, 1671-1684

- Glüge J., Schinkel L., Hungerbühler K., Cariou R., Bogdal C. (2018) Environmental risks of medium-chain chlorinated paraffins (MCCPs): a review. Environ. Sci. Technol. 52, 6743-6760

For more information

- Matsukami H. (2018) Problems on chemical analysis of SCCPs and measurement examples, Presentation at the 29th Annual Conference of Japan Society of Material Cycles and Waste Management (in Japanese)

- Matsukami H. (2018) Trends in POP waste regulations and introduction of SCCP analysis methods, Presentation at the 29th Annual Conference of Japan Society of Material Cycles and Waste Management (in Japanese)

- Matsukami H., Kajiwara N., Kuramochi H. (2019) Contamination status of short-chain chlorinated paraffins and organophosphorus flame retardants in automobile shredder residues from an end-of-life vehicle recycling facility in Japan. Proceedings of the 28th Symposium on Environmental Chemistry, 1B‐06, Japan Society for Environmental Chemistry