- Waste management in Japan

- Circular economy in Japan

- Waste management in Asia

- Disaster waste management

Recycling of Printed Circuit Boards in E-waste: Resource Recovery and Proper Treatment of Brominated Dioxin-like Compounds

Introduction

According to a report of the United Nations University1, the annual global generation of waste electrical and electronic equipment (WEEE or E-waste) in 2016 was about 44.7 million tonnes. It also estimated the total value of valuable materials contained in the E-waste in the same year as astonishing 55 billion Euros. These recyclable materials include iron, copper, aluminum, silver, gold, palladium and plastics. Because of the resource efficiency of E-waste, its recycling has been practiced in many countries. However, only a small portion (about 8.9 million tonnes or 20% of the global E-waste generation in 2016) is reported to be properly collected and recycled. It is assumed that the remaining 80% is mostly either treated for metal recovery by inappropriate means, such as open-burning, or dumped illegally.

Our research team has conducted various surveys on the status of E-waste recycling in the rapidly growing Southeast Asian region as well as Japan (see my article “E-waste Recycling and Movement of Hazardous Chemical Substances” in the January 2015 issue). Our research has focused on proposing appropriate management of E-waste treatment and recycling processes. This article will introduce, among others, our on-going study on the recycling of waste printed circuit boards that have higher resource value than other electronical and electrical parts.

What is a printed circuit board?

Not everyone knows what printed circuit boards look like. Printed circuit boards are important components, or “the heart,” of the electrical and electronic equipment (EEE) around us including smartphones, tablets, personal computers, flat-screen TVs, air conditioners, and refrigerators (Photo 1). Printed circuit boards are said to determine the performance of EEE although they are rarely visible from the outside. A printed circuit board typically comprises a board-like component that is made from insulating materials (e.g., plastics), and electronic components (e.g., integrated circuits (ICs), resistors and capacitors) that are installed on the board and connected by conductive metal materials.

Printed circuit boards contain a variety of metal resources such as copper, gold, silver, platinum, and palladium. Printed circuit boards are generally categorized into two types: control boards containing a high weight percentage of ICs with gold; and power supply boards containing a high weight percentage of copper coils and capacitors. The former type, containing precious metals (e.g., gold and silver) and rare metals (e.g., platinum and palladium), has relatively higher resource value in recycling.

Control board with relatively high value

Control board with relatively high value Power supply board with relatively low value

Power supply board with relatively low valuePrinted circuit boards and brominated dioxin-like compounds

Electrical and electronic equipment often contains chemical substances called flame retardants that reduce the risk of catching fire. Printed circuit boards that use plastics (e.g., epoxy resin and phenolic resin) for the board-like components also contain these flame retardants as additives at a concentration of around 10% (weight) to make the plastics less flammable. In these products, cost-effective brominated flame retardants (BFRs), especially tetrabromobisphenol-A (TBBPA) and epoxidized TBBPA, are widely used. It is known that some BFRs contain toxic brominated dioxin-like compounds as a synthesized impurity. It is also known that these toxic substances are generated by the thermal and photo degradation of BFRs.

As risk management of BFRs is strongly recommended in Japan and globally, actual emissions of brominated dioxin-like compounds must be investigated and analyzed in order to propose sustainable recycling processes for printed circuit boards. They include collecting, transporting, disassembling, crushing and smelting processes. As the smelting process, among them, was assumed to emit the highest level of brominated dioxin-like compounds to the environment, we examined the actual behaviors and emissions of these substances with the cooperation of a non-ferrous metal smelting plant that treats 110,000 tonnes of waste printed circuit boards annually (about 300 tonnes/day) for recycling.

Flows of waste printed circuit board treatment processes

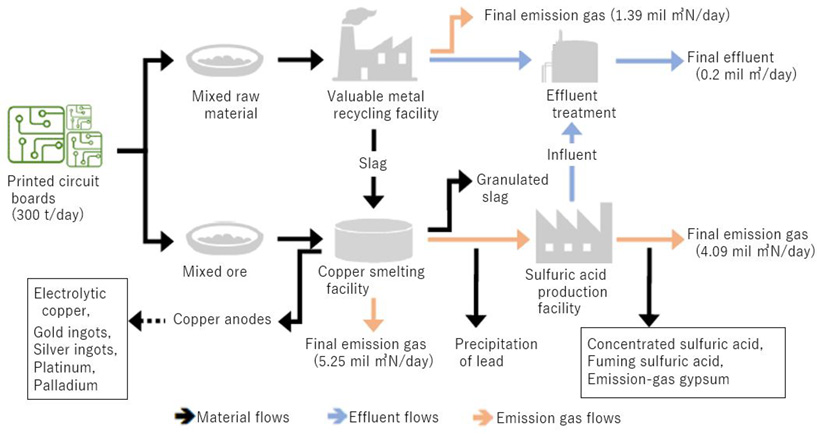

The target of our survey, the smelting plant recovers non-ferrous metals from waste printed circuit boards and treats the emission gas and the effluent discharged during these recovery processes. For these operations, the plant is divided into four sections: a facility for recycling valuable metals, a copper smelting facility, a sulfuric acid production facility, and an effluent treatment facility (Fig. 1).

The facility for recycling valuable metals incinerates and melts raw materials at 1,200 ℃ in a kiln furnace. The raw materials in this case are a mixture of waste printed circuit boards, automobile shredder residue (ASR), home appliances, sludge, and copper-containing ash and dust. The emission gas from the kiln furnace is treated by secondary combustion in a chamber at about 900 ℃. The emission gas from the secondary combustion chamber is rapidly cooled in a cooling tower to about 200 ℃ to decompose and remove dioxins. The gas is further treated by slaked lime being sprayed to it to remove hydrogen chloride, and by bag filters to remove soot and dust. A gas scrubber is used to remove the remaining hydrogen chloride before the treated gas is emitted into the atmosphere through a stack.

In the copper smelting facility, copper concentrate (i.e., a raw material for copper smelting), waste printed circuit boards and silica sand are mixed to prepare ore. The mixed ore and the slag from the kiln furnace of the valuable metal recycling facility are charged to the smelting furnace and refined in the refining furnace to cast copper anodes. From copper anodes, electrolytic copper, gold and silver ingots, platinum and palladium are produced. The emission gas from the smelting and refining furnaces is sent to the sulfuric acid production facility and finally emitted into the atmosphere through a tall exhaust stack after removing ash and dust by bag filters.

In the sulfuric acid production facility, sulfuric acid (i.e., concentrated sulfuric acid and fuming sulfuric acid) and gypsum (i.e., emission gas gypsum) are produced from the sulfur dioxide gas of the smelting and refining furnaces after removing ash and dust. The emission gas is emitted into the atmosphere through a tall exhaust stack after dust and sulfur are removed.

In the effluent treatment facility, the influent from the sulfuric acid production facility containing the dust of the emission gas is treated. This influent and the effluent from the scrubber of the valuable metal recycling facility are both neutralized, and then treated three times to thicken and separate suspended solids as sludge before the treated water is discharged into public waters.

Behaviors and emissions of brominated dioxin-like compounds

In the non-ferrous metal smelting plant, we surveyed and examined the actual behaviors and emissions of brominated dioxin-like compounds. For that, we examined the slag and the final emission gas of the printed circuit board and valuable metal recycling facilities, the granulated slag and the final emission gas of the copper smelting facility, and the final emission gas and the treated effluent of the sulfuric acid production facility. Before the treatment in this plant, the concentration of brominated dioxin-like compounds in waste printed circuit boards was as high as 4.4 ng WHO-TEQ/g that was more than the values of the dioxin emission standard for ash and dust treatment (3.0 ng WHO-TEQ/g) and environmental quality standard for soil (1,000 pg WHO-TEQ/g) for Japan.

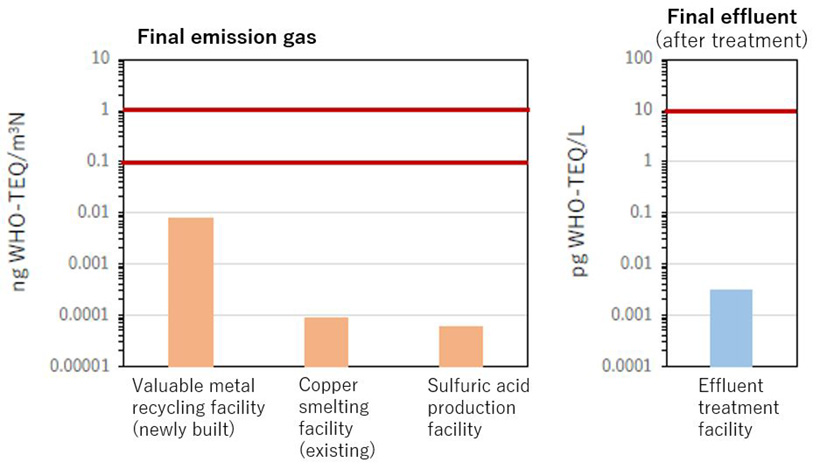

However, after various pollution control processes, the concentrations of dioxin-like compounds were found to be much lower than those in the pre-treatment stage. Even in the above-mentioned case of the treatment of waste printed circuit boards with high dioxin content, the concentration values for the final emission gas of the valuable metal recycling and copper smelting facilities as well as the final emission gas and the treated effluent of the sulfuric acid production facility were lower than the values of the dioxin emission standard for existing waste incinerators (0.1 ng WHO-TEQ/m3N) and for newly built ones (1 ng WHO-TEQ/m3N) as well as the effluent standard for dioxins (10 pg WHO-TEQ/L) (Fig. 2). The concentrations of brominated dioxin-like compounds for the thermal treatment residue were also found to be very low. The value for the slag of the valuable metal recycling facility was 0.00061 ng WHO-TEQ/g, and that for the granulated slag of the copper smelting facility was 0.000010 ng WHO-TEQ/g.

We also examined the total amount of brominated dioxin-like compound input to this non-ferrous metal smelting plant. The total input of dioxins was calculated as 1.3 g WHO-TEQ/day by multiplying the concentration value of brominated dioxin-like compounds in waste printed circuit boards (4.4 ng WHO-TEQ/g) by the processing capacity of the plant (300 t/day). Similarly, the total emission of brominated dioxin-like compounds through the final emission gas and the treated effluent was calculated as about 12 μg WHO-TEQ/day.

Our results show that the non-ferrous metal smelting plant reduced the amount of brominated dioxin-like compounds in the raw materials to 1/110,000 after the treatment. As this plant takes various pollution reduction processes for gas and effluent emissions to reduce environmental impact of this project, we assume that the emission of brominated dioxin-like compounds has also been reduced though these processes.

- Note: Dioxin emission standards for waste incinerators: 1 ng WHO-TEQ/m3N for newly built facilities, and 0.1 ng WHO-TEQ/m3N for existing facilities.

Conclusion

Our survey results suggest that the non-ferrous metal smelting plant properly treats brominated dioxin-like compounds as well as recovers various metal resources from waste printed circuit boards. This, we believe, shows the future direction of recycling printed circuit boards in E-waste in Japan and globally in response to the tremendous amount of WEEE generation and the needs for recycling them. Various products make our lives comfortable, but they will become valueless waste if they are only disposed of. If recyclable materials are thoroughly collected and treated in an environmentally sound manner, they can make valuable resources. We will continue exploring sustainable use and treatment of these resources.

For more information

- Baldé, C.P., Forti V., Gray, V., Kuehr, R., Stegmann, P. (2017) The Global E-waste Monitor - 2017, United Nations University (UNU), International Telecommunication Union (ITU) & International Solid Waste Association (ISWA), Bonn/Geneva/Vienna.

- Suzuki G. (2020) Final report of the research project supported by the Environmental Research and Technology Development Fund: A comprehensive risk management and presentation of toxicity equivalency factors of unintentional brominated dioxin-like compounds (FY2017-2019, 5-1705)