- Waste management in Japan

- Circular economy in Japan

- Waste management in Asia

- Disaster waste management

Circular System for Farmland Recovery Combining Multipurpose Crop Cultivation with Biogas Production

Sorghum cultivation on decontaminated farmlands

Some farmlands of Fukushima Prefecture, Japan, were affected by radionuclides dispersed from a nuclear power plant in the accident following the Great East Japan Earthquake and Tsunami. In their recovery process, these areas were decontaminated by removing topsoil, but many have been left unused for food crop cultivation. Restarting cultivation in these farmlands has been difficult due to many problems such as aging of farming communities, reputational damage to agricultural crops, damage caused by wild animals, declining fertility of soil caused by removal of topsoil for decontamination. The farmlands without topsoil that have been idle for several years have lost not only soil nutrients but also water and nutrient retention properties. As a result, even if usual crops were cultivated, their quality and yield would be insufficient to sustain local agriculture (Fig.1). Municipalities currently arrange weeding works for the farmers who cannot manage their farmlands by themselves. However, these programs have budgetary limitations. Therefore, more proactive programs are needed by the municipalities for these farms to generate additional values and to restart cultivating the lands, in addition to just preserving the current state and waiting for radionuclide content to decrease.

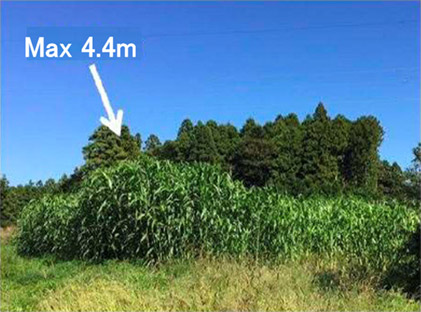

Farmers in the affected areas have been waiting for introduction of new crops and technologies that can help them to cultivate and manage their farmlands with less burden (e.g., labor and cost) until they can resume food crop cultivation. To respond to these needs, we have been conducting a demonstration experiment on cultivation of sorghum in these areas. Specifically, we have been examining a system in which a portion of harvested sorghum is potentially used for cattle feed and the other portion is mixed with cattle manure for anaerobic digestion (i.e., methane fermentation) and biogas production processes. The sorghum variety that we use in this system is drought-resistant and can generate constant yield even in barren land. It leaves up to 20 t/ha rhizome in the soil during a cropping season. These organic matters make effective green manure. In our experiment, we grew sorghum repeatedly in targeted locations spraying the soil with anaerobic digestate liquor (i.e., liquid produced during methane fermentation) that is reported to diversify organisms and improve fertility of farmlands1. Figure 2 shows growth of the sorghum in Tomioka, Fukushima Prefecture four months after the start of cultivation in June 2018. During the period from June to September 2018, the crop reached its maximum height of 4 meters. Apart from the sorghum cultivation, some livestock farms have gradually resumed cattle raising in these areas although high cost of import-dependent feed and a sharp decline in the number of animal waste treatment firms after the earthquake have started to place pressure on them. Supply of cattle feed through sorghum production and collection of livestock manure through anaerobic digestion can help these farms.

Anaerobic digestion of sorghum can generate biogas and electric power

Our experiment used most of the harvested sorghum for anaerobic digestion. Only a small portion was used for cattle feed to test its effectiveness. First, we prepared sorghum silages by anaerobic lactic acid fermentation. Then, we took out a small portion at a time and put them repeatedly into a medium-temperature tank of 5 m3 capacity to demonstrate anaerobic digestion and power generation. In Europe, it is common to cultivate crops only for the purpose of anaerobic digestion, but difficulties in this process have been reported2,3. In our experiment with sorghum, we also faced problems of sorghum’s low wettability and nutrient imbalances.

In the wet fermentation process that we used, solid raw materials are diluted by water or anaerobic digestate liquor. Having low wettability, sorghum stems stay lighter than water, and float in fermentation tanks to form a layer. In our earlier laboratory experiments with sorghum, this layer caused rapid rise in the viscosity of anaerobic digestate liquor to the level where it could not be stirred any more. A similar phenomenon was reported by European researchers2.

Some physicochemical treatment methods were reported to be effective to improve wettability of some raw materials, like rice straws. These methods included acid treatment and a method called steam-explosion treatment that exposes raw materials to high-temperature steam in a high-pressure reaction vessel and then quickly reduces internal pressure. Our laboratory experiment confirmed that sorghum’s viscosity remained low for nearly one year after it had been crushed into small pieces of a few millimeters. Therefore, we also applied this steam-explosion treatment method in our demonstration experiment, though with much smaller electric hammer crusher as we could not use such large-scale equipment.

The second problem, nutrient imbalances, means that the nutrients contained in sorghum do not match with those required by microorganisms to grow. In addition to well-known chemical elements such as carbon, nitrogen, sulfur and phosphorus, these microorganisms require trace metal elements, such as iron, nickel, molybdenum, and cobalt, as nutrients4. However, most of them are not found in sorghum. According to a site survey on anaerobic digestion facilities, many cases of similar nutrient imbalances have been reported from the facilities that use crops as raw materials5. Our laboratory experiment proved that adding a little amount of such missing nutrients to raw materials enables the activity of anaerobic digestion to almost double. So, a tank was added to our demonstration experiment facilities to supply the lacking nutrients to sorghum. In this way, we achieved stable anaerobic digestion of sorghum. Figure 3 shows the demonstration of power generation from this anaerobic digestion of sorghum in January 2019.

Our next step will be to examine issues that are expected in various applications of this method and to suggest ways to manage them. These issues include difficulties in accepting various raw materials; low water wettability and nutrient imbalances mentioned in this article; confirming safety of crops when they are partially contaminated by high content of radiocesium (e.g., understanding behavior of radiocesium and safety management)6.

References

- Sapp M., Harrison M., Hany U., Charlton A., Thwaites R. (2015) Comparing the effect of digestate and chemical fertiliser on soil bacteria, Applied Soil Ecology, 86, 1-9

- Thamsiriroj, T., Murphy, J. D. (2010) Difficulties Associated with Monodigestion of Grass as Exemplified by Commissioning a Pilot-Scale Digester, Energy & Fuels, 24(8), 4459-4469

- Thamsiriroj, T., Nizami, A.S., Murphy, J.D. (2012) Why does mono-digestion of grass silage fail in long term operation?, Applied Energy, 95, 64-76

- Hendriks, A.T.W.M., van Lier, J.B., de Kreuk, M.K. (2018) Growth media in anaerobic fermentative processes: The underestimated potential of thermophilic fermentation and anaerobic digestion, Biotechnol Adv., 36(1), 1-13

- Lindorfer, H., Romhold, D., Frauz, B. (2012) Nutrient and trace element supply in anaerobic digestion plants and effect of trace element application, Water Sci. Technol., 66(9), 1923-1929

- Ecolomy et al. (2019) 2018 report of the Fukushima Innovation Coast Framework projects (external link, in Japanese language only)

- Kobayashi T., Kuramochi H., Xu K-Q., Aizawa T. (2020) Bioleaching and removal of radiocesium in anaerobic digestion of biomass crops: Effect of crop type on partitioning of cesium. Biotechnology Reports, 28, e00561